Canada is one of the harshest real-world testing environments for heavy-duty pickup trucks. Long winters, extreme temperature swings, rural infrastructure, long transport distances, and continuous load stress create conditions that go far beyond standard “work use.” In theory, a Dodge Ram is built for tough jobs. In practice, long-term operation in Canadian working environments exposes weaknesses that don’t show up in brochures or short-term testing.

This article breaks down what actually fails, why it fails, and what long-term owners, fleet operators, farmers, miners, and contractors experience after years of real deployment. Not theory. Reality.

Extreme Cold as a Mechanical Stress Multiplier

Cold in Canada isn’t just uncomfortable — it’s mechanically destructive. At -25°C to -40°C, materials behave differently, fluids thicken, tolerances shrink, and electronics become unstable.

What starts failing first:

- Rubber components (hoses, seals, gaskets) become brittle

- Plastic connectors crack and lose structural integrity

- Electrical insulation stiffens and micro-fractures

- Battery systems lose capacity dramatically

- Sensors and connectors suffer condensation and corrosion cycles

Cold amplifies every existing weakness in the system. A marginal seal becomes a leak. A weak connector becomes a fault code. A slightly degraded battery becomes a no-start scenario.

Long-term cold exposure creates progressive degradation, not instant failure — which is why these problems appear after years, not months.

Reality: Canadian winters don’t cause single failures — they accelerate system aging.

Long-Distance Load Stress and Thermal Fatigue

Unlike urban driving cycles, Canadian work trucks often operate under continuous load conditions:

- Long highway distances

- Heavy trailers

- Equipment transport

- Constant towing

- High RPM thermal cycling

- Extended operating hours

This creates thermal fatigue, not just mechanical wear.

Systems most affected:

- Transmission cooling systems

- Turbochargers

- Exhaust systems

- EGR circuits

- DEF systems

- Intercoolers

- Cooling fans and radiators

Heat cycling causes metal fatigue, seal hardening, and micro-warping in components. Over time, this leads to:

- Boost leaks

- Exhaust backpressure

- Turbo efficiency loss

- Cooling inefficiency

- Sensor inaccuracies

- Regeneration failures

These aren’t “broken parts” — they are efficiency collapses, which slowly degrade performance, fuel economy, and reliability.

Emissions Systems: The Biggest Long-Term Failure Point

In real Canadian work environments, emissions systems are the #1 long-term reliability bottleneck.

Not because they’re poorly engineered — but because they were designed for regulated duty cycles, not real-world heavy use.

Chronic failure points:

- DPF clogging

- EGR carbon buildup

- DEF crystallization

- SCR faults

- Sensor false readings

- Regeneration cycle failures

Why this happens:

- Short runs in cold weather prevent proper regen

- Long idling creates carbon buildup

- Load + cold = incomplete combustion

- Temperature instability disrupts sensor accuracy

- DEF systems hate freezing/thawing cycles

This creates a loop:

Fault → limp mode → forced regen → higher stress → more faults

Over years of use, the truck becomes software-restricted, not mechanically broken.

Electronics and Software Dependency

Modern Dodge Rams are software-controlled machines, not just mechanical trucks.

That creates a different type of failure model:

- Sensor dependency

- Software interlocks

- Fault-triggered power reduction

- Regeneration logic control

- Emissions-based torque limiting

- Throttle mapping restrictions

This means many “failures” are not physical damage — they are software-induced limitations.

Why Performance Degradation Feels Worse Than Mechanical Failure

Mechanical failures are visible and fixable.

System degradation is invisible and frustrating.

Symptoms owners report:

- Sluggish throttle response

- Unpredictable power delivery

- Inconsistent fuel economy

- Random fault codes

- Limp modes without real mechanical damage

- Loss of towing performance

- Reduced engine efficiency

Where Smart System Optimization Becomes a Solution

At this stage, the problem is no longer purely mechanical — it’s system architecture.

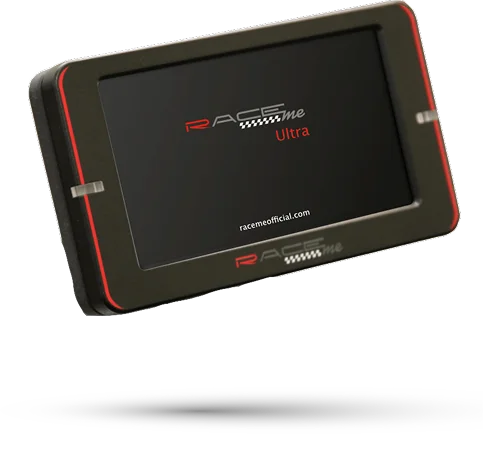

Tools like the RaceMe ULTRA are not about raw power increases — they address system efficiency, software limitations, and operational stability.

RaceMe ULTRA works at the control-system level by:

- Optimizing fuel mapping

- Stabilizing throttle response

- Improving torque curves

- Reducing inefficient software restrictions

- Improving combustion efficiency

- Enhancing thermal management

- Restoring consistent power delivery

In harsh long-term working conditions, this matters more than peak horsepower.

Because the real problem isn’t lack of power — it’s unstable system behavior caused by emissions logic, regeneration cycles, and software constraints under non-ideal conditions.

RaceMe ULTRA doesn’t “fight the truck” — it aligns the software with real-world use instead of laboratory duty cycles.

RaceMe ULTRA Diesel Tuner

- DPF/EGR/DEF Delete Options

- Works with RAM 2500/3500/4500/5500

- +200 HP Performance Boost

- Real–Time Monitoring & Tuning

- Easy Plug & Play Install + Updates Free

If you’re running a Dodge Ram in real Canadian working conditions — not weekend towing, not city driving, but real deployment — then optimizing the system architecture isn’t a luxury.

It’s a long-term reliability decision. And that’s exactly where a specialized diesel performance tuners can bring real value.

FAQ – Dodge RAM Performance Upgrades in Canada

Is performance tuning legal for Dodge RAM trucks in Canada?

Performance tuning itself is not illegal, but it must comply with provincial regulations and emissions requirements. The legality depends on how the vehicle is used, inspected, and registered.

Will a performance upgrade affect reliability?

When done correctly with a balanced solution, performance tuning can actually improve drivability and reduce strain during towing. Poorly designed or overly aggressive tuning, however, can reduce reliability.

Is RaceMe Ultra suitable for daily driving?

Yes. RaceMe Ultra is designed for everyday use, including commuting, towing, and long-distance driving. The focus is on smooth power delivery rather than extreme output.

Can performance tuning help with towing?

Absolutely. One of the biggest benefits is improved low-end torque and throttle response, which makes towing more controlled and less stressful for the engine.

Is installation complicated?

No. RaceMe Ultra uses a plug-and-play setup, allowing installation without permanent modifications or advanced mechanical knowledge.