If you own a truck powered by 6.7 Cummins diesel engine, you already know it’s built for torque, durability, and serious work. But even one of the best diesel engines ever produced has room to breathe better. One of the most effective and talked-about upgrades among Cummins owners is the downpipe.

So what exactly is a downpipe, and why does it make such a noticeable difference in performance, exhaust flow, turbo efficiency, and EGT control on the 6.7 Cummins? Let’s break it down in a way that’s practical, honest, and based on how these engines actually behave in the real world.

What Is a Downpipe? (Simple Explanation)

A downpipe is the section of exhaust piping that connects directly to the turbocharger outlet and routes exhaust gases downward into the rest of the exhaust system. In turbocharged diesel engines like the 6.7L Cummins, the downpipe is one of the most critical components for managing exhaust flow.

Think of it as the engine’s first “exit door” after combustion. If that door is narrow, restrictive, or poorly shaped, everything behind it suffers.

On the factory 6.7 Cummins, the stock downpipe is designed primarily to meet emissions regulations, noise limits, and packaging constraints, not performance. As a result, it often becomes a major bottleneck for exhaust gases.

Why the Downpipe Matters More on a Turbo Diesel

Unlike naturally aspirated engines, turbo diesels rely on exhaust energy to spin the turbocharger. Any restriction after the turbo increases backpressure, which directly works against turbine efficiency.

On the 6.7 Cummins, this matters even more because:

- It produces high exhaust volume

- It runs higher boost pressures

- It is commonly used for towing, hauling, and tuning

A restrictive downpipe doesn’t just limit power—it affects thermal efficiency, reliability, and drivability.

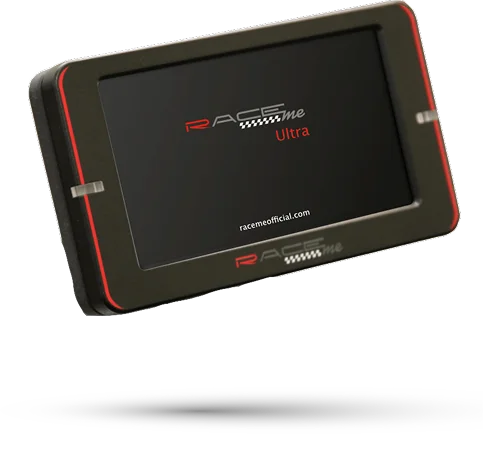

RaceMe ULTRA Diesel Tuner

- DPF/EGR/DEF Delete Options

- Works with RAM 2500/3500/4500/5500

- +200 HP Performance Boost

- Real–Time Monitoring & Tuning

- Easy Plug & Play Install + Updates Free

The Biggest Problem with the Stock 6.7 Cummins Downpipe

The factory downpipe on the 6.7 Cummins has several well-known limitations:

- Crushed or flattened sections to fit around the firewall

- Tight bends that disrupt exhaust flow

- Smaller internal diameter than ideal for high exhaust volume

- Designed to work with DPF and emissions hardware, not free flow

All of this leads to higher exhaust backpressure, which creates a chain reaction of inefficiencies throughout the engine.

How a Performance Downpipe Improves 6.7 Cummins Performance

Upgrading to a high-flow aftermarket downpipe addresses these issues immediately. Here’s how it improves performance step by step.

1. Reduced Exhaust Backpressure

This is the single biggest benefit.

A larger-diameter, smooth-bent downpipe allows exhaust gases to exit the turbo more easily. Lower backpressure means:

- Less resistance against the turbine

- Reduced strain on exhaust valves

- Improved overall engine efficiency

For the 6.7 Cummins, this translates into a more responsive and relaxed engine, especially under load.

2. Faster Turbo Spool and Better Throttle Response

When exhaust gases flow freely, the turbocharger can:

- Spool earlier

- Maintain boost more consistently

- Respond quicker to throttle input

Many Cummins owners notice that after installing a downpipe, the truck feels more alive at lower RPMs, especially when towing or accelerating from a stop.

3. Lower Exhaust Gas Temperatures (EGTs)

High EGTs are one of the biggest enemies of diesel engines, particularly under heavy load.

A restrictive downpipe traps heat near the turbo. A performance downpipe:

- Moves heat away faster

- Reduces thermal stress on the turbocharger

- Helps keep EGTs more stable during towing or tuning

Lower EGTs mean safer towing, more headroom for tuning, and improved long-term reliability.

4. Increased Horsepower and Torque Potential

On its own, a downpipe won’t magically add massive horsepower—but it unlocks power that’s already being restricted.

When combined with:

- ECU tuning

- Intake upgrades

- Free-flowing exhaust systems

…the downpipe becomes a critical supporting modification that allows the 6.7 Cummins to reach its true potential.

5. Improved Fuel Efficiency (Yes, Really)

This surprises many people.

By reducing backpressure and improving combustion efficiency, the engine doesn’t have to work as hard to produce the same power. In many real-world cases, owners report:

- Slightly improved MPG

- More consistent fuel economy under load

Especially for highway driving or towing, the efficiency gains can be noticeable.

Unlock the absolute pinnacle of power, efficiency, and drivability. Our experts craft every tune to perfectly match YOUR RAM, YOUR modifications, and YOUR goals.

Downpipe Diameter: What Works Best for the 6.7 Cummins?

Most high-quality aftermarket downpipes for the 6.7 Cummins fall into these ranges:

- 4-inch downpipes – Excellent balance for daily driving and towing

- 5-inch downpipes – Ideal for high-power builds and aggressive tuning

The key isn’t just diameter—it’s smooth mandrel bends, consistent internal diameter, and proper turbo flange fitment.

Sound Differences After Installing a Downpipe

While the downpipe is not a muffler, it does influence exhaust tone.

Expect:

- Slightly deeper exhaust note

- More pronounced turbo whistle

- Cleaner sound under acceleration

Paired with an aftermarket exhaust, the sound becomes more refined and purposeful, not obnoxious.

Is a Downpipe Worth It on a Stock 6.7 Cummins?

Yes—and here’s why.

Even on a completely stock truck:

- The factory downpipe is still restrictive

- The engine still benefits from lower backpressure

- Turbo efficiency still improves

While the gains are larger on tuned trucks, many owners install a downpipe as a foundational upgrade before any tuning.

Installation Considerations (What to Expect)

Installing a downpipe on the 6.7 Cummins can be:

- Moderately difficult

- Tight in the engine bay

- Easier with the right tools and patience

Key considerations:

- Firewall clearance

- Turbo flange alignment

- Compatibility with existing exhaust components

Professional installation is recommended if you want perfect fitment and zero headaches.

Common Myths About Downpipes on Diesel Trucks

Myth 1: “Downpipes are only for race trucks.”

False. They’re just as valuable for towing and daily driving.

Myth 2: “You won’t feel a difference.”

Most drivers notice smoother power delivery almost immediately.

Myth 3: “It hurts reliability.”

In reality, lower EGTs and reduced backpressure improve engine longevity.